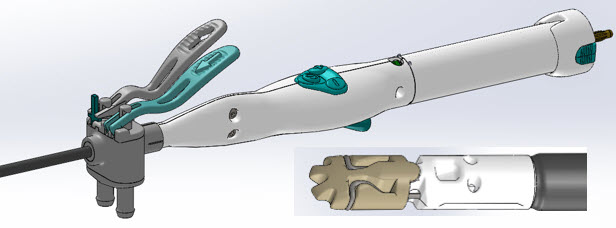

Laparoscopic Differential Dissector (DDL)

Designing the

Laparoscopic Differential Dissector (DDL) has been an iterative process, driven by surgeon evaluation and feedback. I've

designed, fabricated and tested many prototypes a few of which are pictured below. These devices are featured in the videos

on our website.

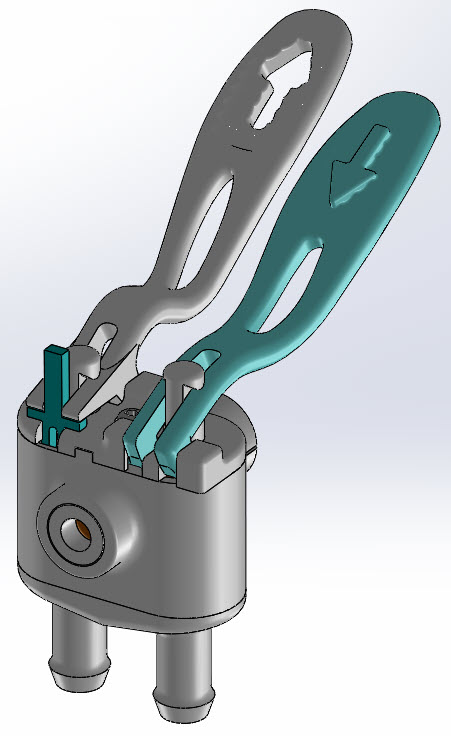

The DDL is an

FDA class 2 device that has a 5mm OD shaft and embodies:

- powered

blunt dissection,

- single

hand, surgeon deployable electrosurgical cut and

coagulation hook,

- optional

suction / irrigation / smoke

evacuation module

Engineering challenges include:

-

Oscillating drive train that operates at high frequencies and

amplitudes while tolerating the very large forces and bending moments

that

surgeons routinely produce.

- High

frequency, high voltage electrical current that must run

through the device subject to IEC 60601 testing and design criteria.

- Device

must sense when electrode is deployed and prohibit

simultaneous use of powered blunt dissection.

- Device

must have provision for an optional device to control gravity fed

irrigation fluids and interface with a surgical vacuum source.

- Batteries

for powered blunt dissection must be removeable at the

end of surgery for disposal in separate hospital waste stream.

- Device is

single use disposable so the design must minimize

resource consumption and be as inexpensive as possible. The

design also

must defy attempts to resterilize and reuse.

- The

hardware that passes through the shaft must be sealed to

prevent loss of insufflation pressure and escape of fluids during

use of

suction / irrigation module.

The

design that we settled on enables effortless and intuitive control of all functions.

DDL with suction / irrigation module (SIM) installed

Optional suction / irrigation module (SIM) controls gravity fed or pump fed irrigation as well as vacuum.

The DDL is completely ready for manufacturing. We have worked with our injection molding vendors to tailor the plastic parts for optimal molding and we've identified vendors for every part.

Images shown on this page are property of Physcient Inc. and have been

approved for public release. © 2020 Physcient Inc.